A revolutionary new plasterboard design incorporating seaweed could reduce the carbon footprint of building materials and contribute to safer, more liveable homes in Aotearoa New Zealand.

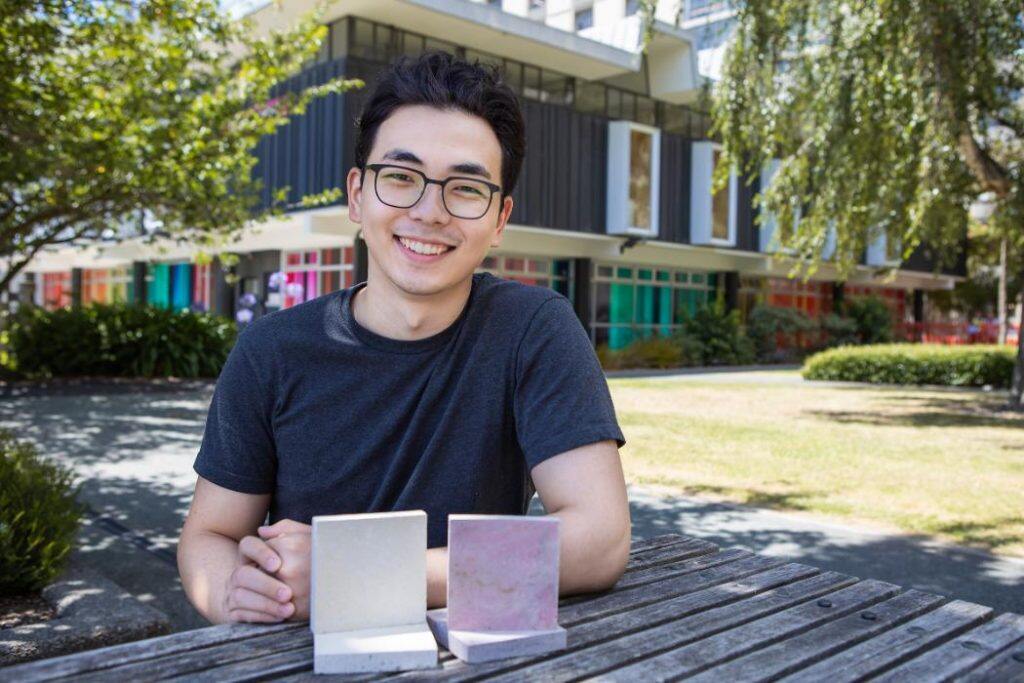

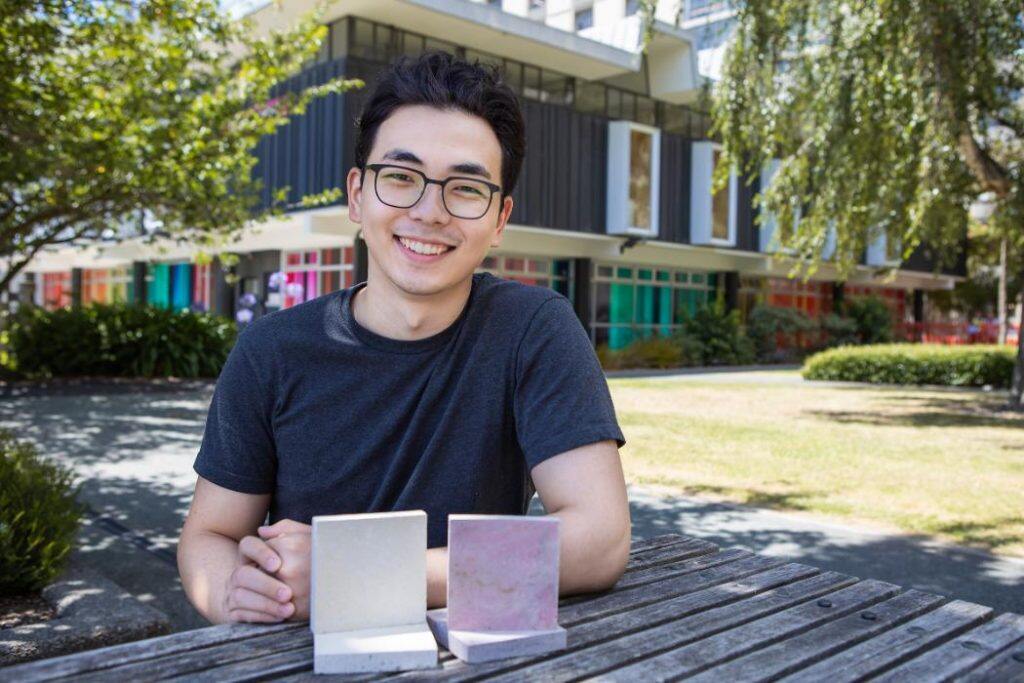

University of Canterbury (UC) Bachelor of Product Design student Andy (Minhong) Park has developed a biocomposite wall panel that uses algae – or seaweed – as a bio-filler as part of his final-year Industrial Design project.

The plasterboard has fireproofing and moisture control features and is a low-cost material that could help reduce the building industry’s carbon footprint.

“Currently the building industry contributes 20% of our country’s carbon emissions,” Park says. “As the sector faces the challenge of reducing carbon emissions but building more houses, and with plasterboard used in almost every home, seaweed plasterboard offers a viable green alternative.

“Seaweed is fast-growing at 0.5 metres per day and is capable of sequestering around 173 million metric tons of carbon annually. It’s easy to cultivate and can be farmed offshore, not competing for farmable land with other bio-based materials, making it an attractive, low-cost farming commodity. Because seaweed can absorb carbon underwater, large wall-panel manufacturers could employ seaweed farming as a carbon offset by growing it.”

Seaweed bio-filler also contributes to warmer, drier, safer homes, and Park says preliminary testing indicates fire performance at the level of commercially available products.

“Seaweed has been proven to reduce ignition risks, increase flame retardancy, and promote auto-extinguishing behaviour of seaweed-based composite systems because it contains boron, a natural fire retardant. When seaweed is combined with cement, the strength of the resulting concrete is increased. Seaweed and its main constituent, alginate, have also been demonstrated to have high thermal stability and low thermal conductivity so the plasterboard would take longer to break down during a fire,” he says.

“Seaweed is also recognised for its ability to absorb and release moisture and is a greener alternative to traditional passive fire protection materials due to the absence of non-recyclable elements. This also makes it able to be recycled and used as a fertiliser.”

The finished seaweed plasterboard product has a glossy marble surface, coloured green, red or brown depending on the type of seaweed used.

The 12-week project was supervised by University of Canterbury Product Design Senior Lecturer Dr Tim Huber in collaboration with UC Fire Engineering Lecturer Dr Dennis Pau. While still in the early stages of research, design and testing, the team is working with the University of Canterbury’s Research and Innovation team to develop a commercialisation plan, and Kaiārahi Rangahau Māori to identify suitable species of seaweed for product development and marine agriculture.

The project recently won the UC Innovation Jumpstart Greatest Commercial Potential Award and accompanying $20,000 prize.